Ground Penetrating Radar

In 2005-06 the Oak Tree Foundation, Southern California Equine Foundation and Dolly Green Foundation funded research into the imaging of the base on racing surfaces. Design of a system tailored to racing surfaces was performed by Geophysical Survey Systems, one of the world’s leading companies providing ground penetrating radar equipment based in Nashua, New Hampshire.

The principles of ground penetrating radar (GPR) are quite straightforward making use of electromagnetic waves to see inside the surface of the racetrack, much like ultrasound, X-ray or other imaging methods (https://www.youtube.com/user/GPRbyGSSI). The resulting data is then synchronized with simultaneous data from GPS data to create a map of the interior of the racing surfaces.

Among the information that can be obtained from the GPR data is drainage, showing wet or dry areas of turf or dirt track. Areas of inconsistent composition where either synthetic or dirt materials may have become segregated are also evident in many cases where for example clay is lost due to runoff in a dirt surface or fiber accumulates in the synthetic racing surface. Or, most commonly where there is an area with an inconsistent amount of material over the base or damage to the base from water, maintenance or even frost damage. All of this, like any imaging method, requires careful data interpretation.

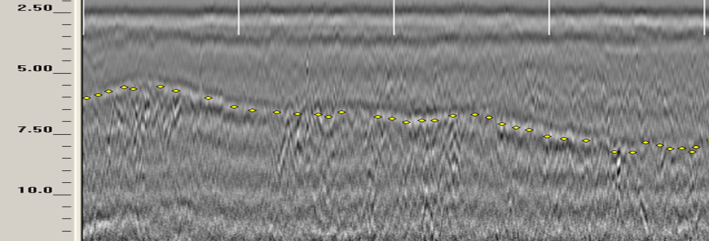

Simple cross sectional views of the racetrack can be used to identify areas where as in the example the amount of cushion over the hardpan is inadequate

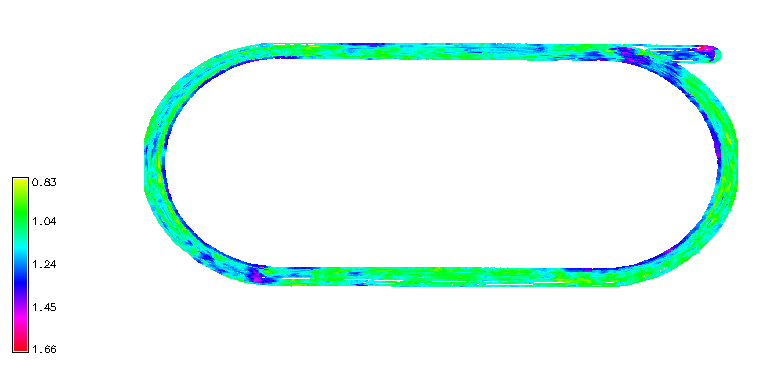

The way that the data is usually presented for the maintenance personnel at the racetrack is through a color coded map. Often this type of map is useful for not only identifying issues but by comparing the map to locations of various activities on the track a longer term solution is possible. Most common is inconsistent cushion depth along the rail caused by issues with grading or harrow set up. Water flow across or through the surface can impact consistency of dirt or turf tracks. If the track is always maintained in one direction then a low spot will develop on the entrance to the turn with the material deposited on the exit from the turn, just simply a consequence of the inertia of the harrow. Finally both traffic from horses, maintenance equipment and other events can result in areas on the track which are less consistent.

The goal with all of this testing is to provide immediate feedback for the maintenance team at the racetrack. Often these issues can be resolved while the test team is still on site and the track will be retested to make sure that the solution worked. Like all of the work of Biologically Applied Engineering, we are focused on making measurements to support track maintenance personnel to ensure that the most consistent possible surface is provided for racing and training. Radar map of a Thoroughbred track showing deep areas on exits of turns where material from harrow is deposited and areas of the track where the equipment enters and material is deposited on the track. The inside of the turns are also deep where the harrow has pushed material to the inside of the track. All of these issues were easily addressed with one afternoon of work by an experienced grader operator.

© 2015 Biologically Applied Engineering